Product Information

Photolithography.com offers spin coaters, mask aligners, developing equipment, and etching equipment for laboratory applications.

|

|

|

|

|

|

|

| <Maximum Substrate Size> | <Maximum Substrate Size> | |||||

| 4 in. 6 in. 8 in. 12 in. |

●MS-B100 ●MS-B150 ●MS-B200 ●MS-B300 |

100 × 100 mm 150 × 150 mm |

●MS-B200 (Shield type) ●MS-B300 (Shield type) |

●Sample Stages (standard) ●Sample Stages (customized) |

||

Spin Coaters

MS-B100 Spin Coater

[Model suitable for 4-inch-dia. wafers and 75 × 75 mm substrates]

Product Specifications

| Maximum substrate size | 4-inch-dia. wafers or 75 × 75 mm substrates |

|---|---|

| Rotational speed (rpm) | 20 to 8,000 |

| Rotational accuracy | ±1 rpm (under load) |

| Motor | AC servomotor |

| Cover | Acrylic |

| Inside diameter of spinning chamber | 220 mm dia. |

| Numbers of steps and patterns | 100 steps × 10 patterns |

| Time setting | 999.9 sec |

| Safety interlock | Vacuum (included as standard) Cover (optional) |

| Dripping equipment | Cannot be attached. |

| Working vacuum pressure | -0.08 to -0.1 MPa |

| Power supply | 100 to 240 V AC, 5 A |

| Outside dimensions (mm) | 259 W × 246 H × 330 D |

| Weight | 10 kg |

Note: Specifications are subject to change without notice.

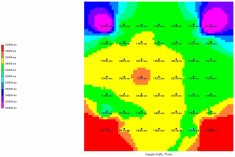

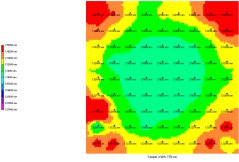

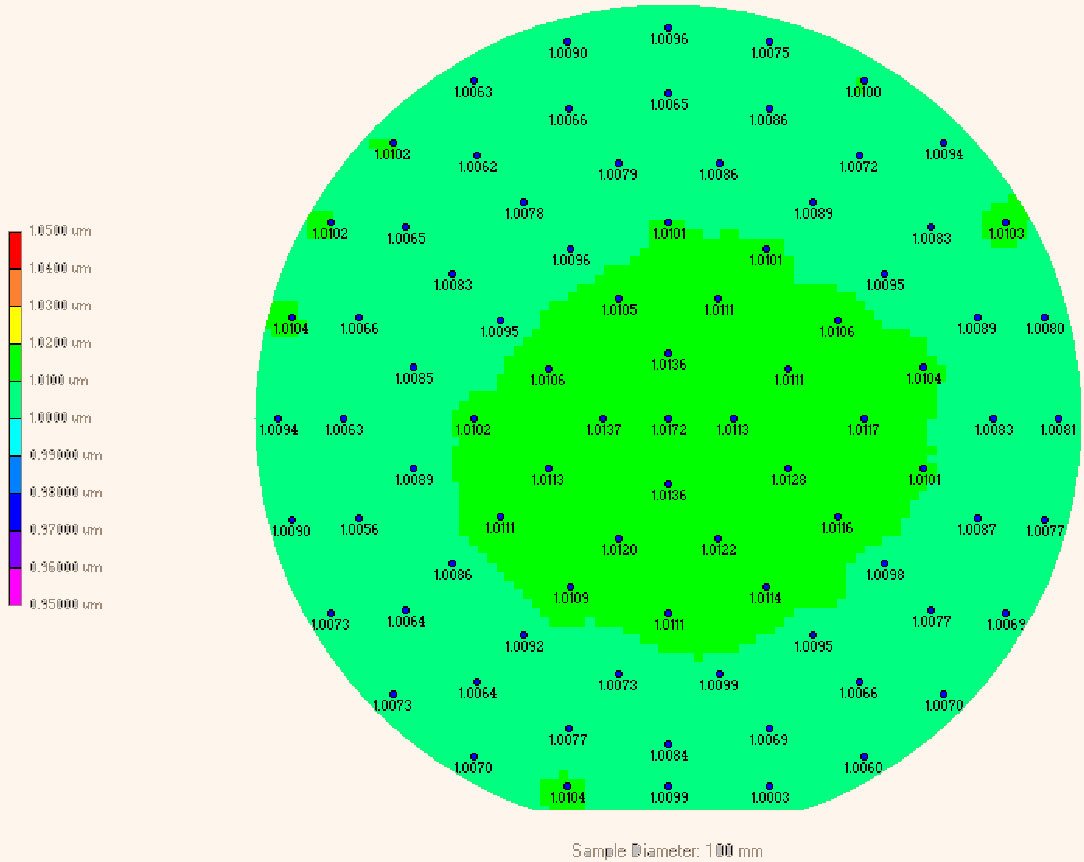

Coating Thickness Distribution Data

| Model used | MS-B100 |

|---|---|

| Coating thickness measurement system | F50 (from Filmetrics) |

| Resist | OFPR-800LB (from Tokyo Ohka Kogyo Co., Ltd.) |

| Substrate size | 4-inch-dia. silicon wafers |

| Target coating thickness | 1 μm |

| Coating thickness distribution | ±0.8% |

MS-B150 Spin Coater

[Model suitable for 6-inch-dia. wafers and 100 × 100 mm substrates]

Product Specifications

| Maximum substrate size | 6-inch-dia. wafers or 100 × 100 mm substrates |

|---|---|

| Rotational speed (rpm) | 20 to 7,000 |

| Rotational accuracy | ±1 rpm (under load) |

| Motor | AC servomotor |

| Cover | Acrylic |

| Inside diameter of spinning chamber | 290 mm dia. |

| Numbers of steps and patterns | 100 steps × 10 patterns |

| Time setting | 999.9 sec |

| Safety interlock | Vacuum (included as standard) Cover (optional) |

| Dripping equipment | Optional |

| Working vacuum pressure | -0.08 to -0.1 MPa |

| Power supply | 100 to 240 V AC, 5 A |

| Outside dimensions (mm) | 352 W × 303 H × 432 D |

| Weight | 16 kg |

Note: Specifications are subject to change without notice.

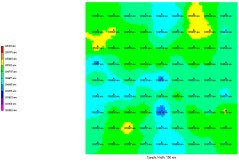

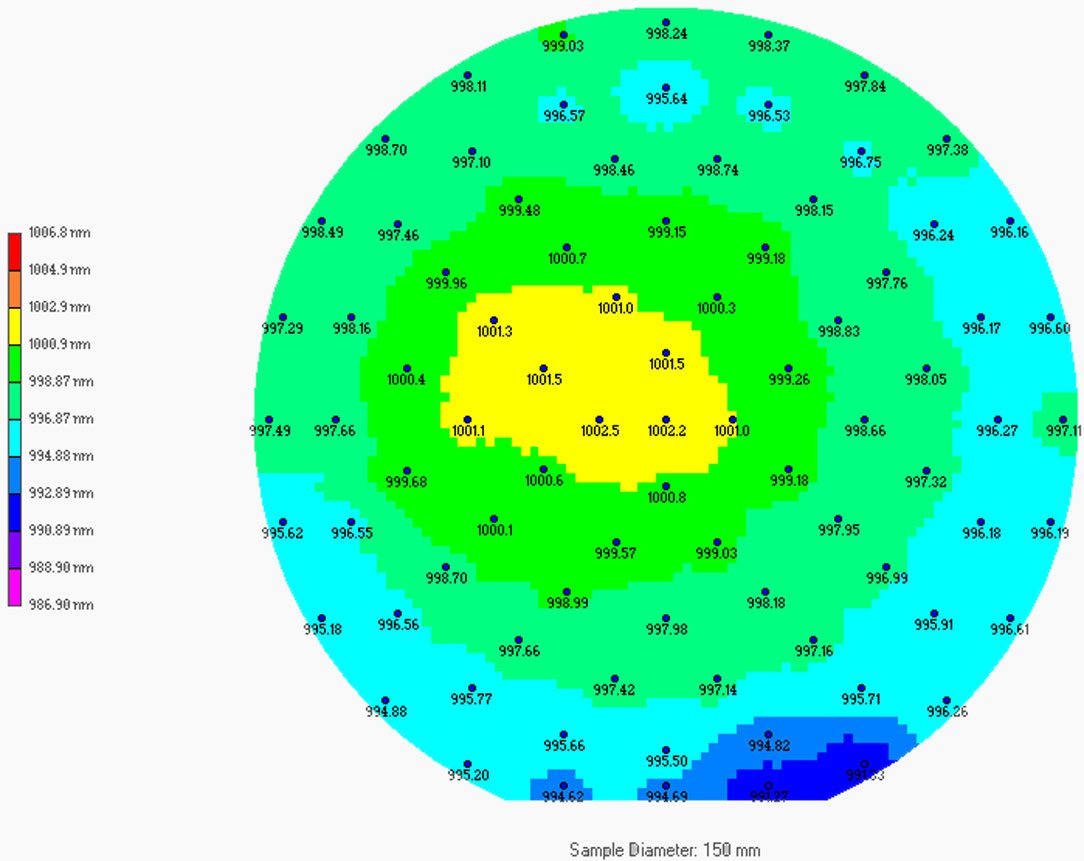

Coating Thickness Distribution Data

| Model used | MS-B150 |

|---|---|

| Coating thickness measurement system | F50 (from Filmetrics) |

| Resist | OFPR-800LB (from Tokyo Ohka Kogyo Co., Ltd.) |

| Substrate size | 6-inch-dia. silicon wafers |

| Target coating thickness | 1 μm |

| Coating thickness distribution | ±0.6% |

MS-B200 Spin Coater

[Model suitable for 8-inch-dia. wafers and 150 × 150 mm substrates]

Product Specifications

| Maximum substrate size | 8-inch-dia. wafers or 150 × 150 mm substrates |

|---|---|

| Rotational speed (rpm) | 20 to 5,000 |

| Rotational accuracy | ±1 rpm (under load) |

| Motor | AC servomotor |

| Cover | Polycarbonate |

| Inside diameter of spinning chamber | 360 mm dia. |

| Numbers of steps and patterns | 100 steps × 10 patterns |

| Time setting | 999.9 sec |

| Safety interlock | Vacuum (included as standard) Cover (included as standard) |

| Dripping equipment | Optional |

| Working vacuum pressure | -0.08 to -0.1 MPa |

| Power supply | 100 to 240 V AC, 5 A |

| Outside dimensions (mm) | 500 W × 335 H × 583 D |

| Weight | 28 kg |

Note: Specifications are subject to change without notice.

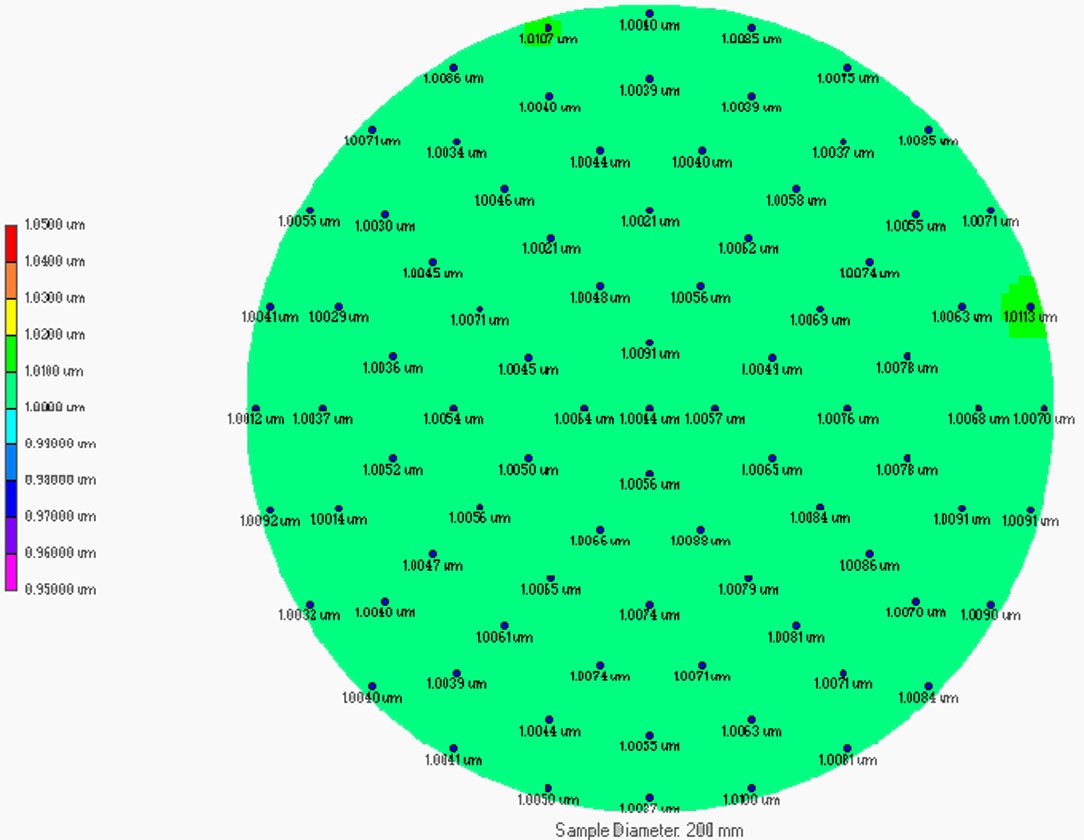

Coating Thickness Distribution Data

| Model used | MS-B200 |

|---|---|

| Coating thickness measurement system | F50 (from Filmetrics) |

| Resist | OFPR-800LB (from Tokyo Ohka Kogyo Co., Ltd.) |

| Substrate size | 8-inch-dia. silicon wafers |

| Target coating thickness | 1 μm |

| Coating thickness distribution | ±0.5% |

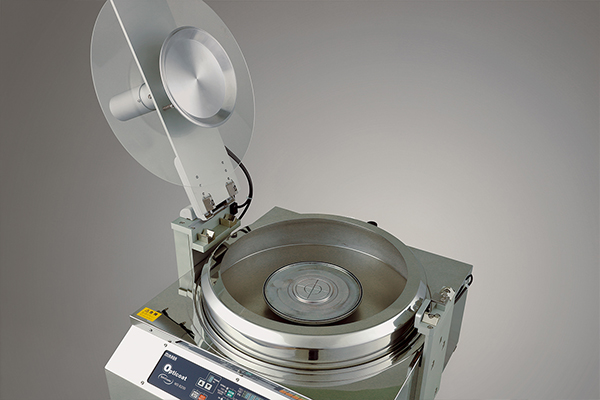

MS-B300 Spin Coater

[Model suitable for 12-inch-dia. wafers and 200 × 200 mm substrates]

Product Specifications

| Maximum substrate size | 12-inch-dia. wafers or 200 × 200 mm substrates |

|---|---|

| Rotational speed (rpm) | 20 to 5,000 |

| Rotational accuracy | ±1 rpm (under load) |

| Motor | AC servomotor |

| Cover | Polycarbonate |

| Inside diameter of spinning chamber | 500 mm dia. |

| Numbers of steps and patterns | 100 steps × 10 patterns |

| Time setting | 999.9 sec |

| Safety interlock | Vacuum (included as standard) Cover (included as standard) |

| Dripping equipment | Optional (Up to two arms can be attached.) |

| Working vacuum pressure | -0.08 to -0.1 MPa |

| Power supply | 200 to 240 V AC, single-phase, 5 A |

| Outside dimensions (mm) | 545 W × 432 H × 654 D |

| Weight | 55 kg |

| Optional | Centering jig |

Note: Specifications are subject to change without notice.

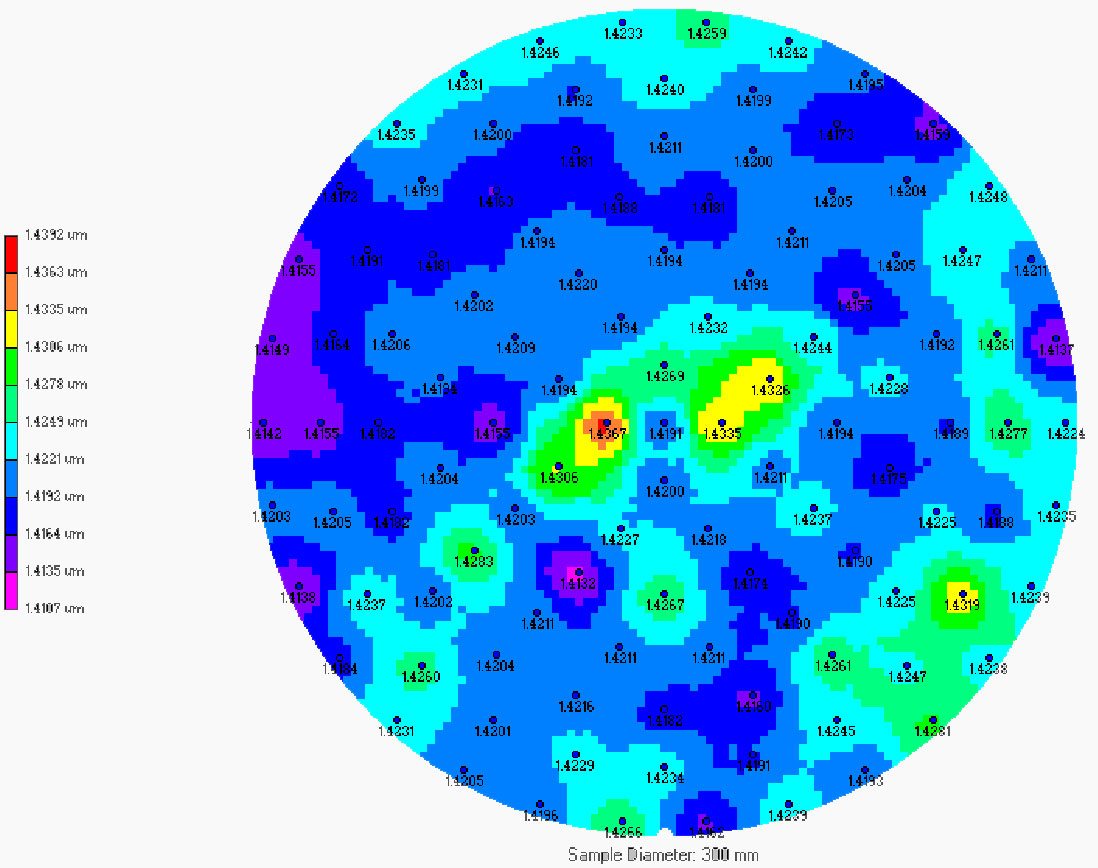

Coating Thickness Distribution Data

| Model used | MS-B300 |

|---|---|

| Coating thickness measurement system | F50 (from Filmetrics) |

| Resist | OFPR-800LB (from Tokyo Ohka Kogyo Co., Ltd.) |

| Substrate size | 12-inch-dia. silicon wafers |

| Target coating thickness | 1 μm |

| Coating thickness distribution | ±0.8% |

MS-B200 Spin Coater (Shield type)

[Shield model specifically designed for small square substrates]

Product Specifications

| Maximum substrate size | 100 × 100 mm substrates |

|---|---|

| Rotational speed (rpm) | 20 to 3,000 |

| Rotational accuracy | ±1 rpm (under load) |

| Motor | AC servomotor |

| Sealing cover | Aluminum and Delrin |

| Inside diameter of spinning chamber | 360 mm dia. |

| Numbers of steps and patterns | 100 steps × 10 patterns |

| Time setting | 999.9 sec |

| Safety interlock | Vacuum (included as standard) Cover (included as standard) |

| Dripping equipment | Cannot be attached. |

| Working vacuum pressure | -0.08 to -0.1 MPa |

| Utility | Air: 0.3 MPa (for upper cylinder) |

| Power supply | 100 to 240 V AC, 5 A |

| Outside dimensions (mm) | 540 W × 460 H × 630 D |

| Weight | 44 kg |

Note: Specifications are subject to change without notice.

Coating Thickness Distribution Data

MS-B300 Spin Coater (Shield type)

[Shield model specifically designed for big square substrates]

Product Specifications

| Maximum substrate size | 150 × 150 mm substrates |

|---|---|

| Rotational speed (rpm) | 20 to 3,000 |

| Rotational accuracy | ±1 rpm (under load) |

| Motor | AC servomotor |

| Sealing cover | Aluminum and Delrin |

| Inside diameter of spinning chamber | 500 mm dia. |

| Numbers of steps and patterns | 100 steps × 10 patterns |

| Time setting | 999.9 sec |

| Safety interlock | Vacuum (included as standard) Cover (included as standard) |

| Dripping equipment | Optional (Only one arm can be attached.) |

| Working vacuum pressure | -0.08 to -0.1 MPa |

| Utility | Air: 0.3 MPa (for upper cylinder) |

| Power supply | 200 to 240 V AC, single-phase, 5 A |

| Outside dimensions (mm) | 570 W × 590 H × 650 D |

| Weight | 65 kg |

Note: Specifications are subject to change without notice.

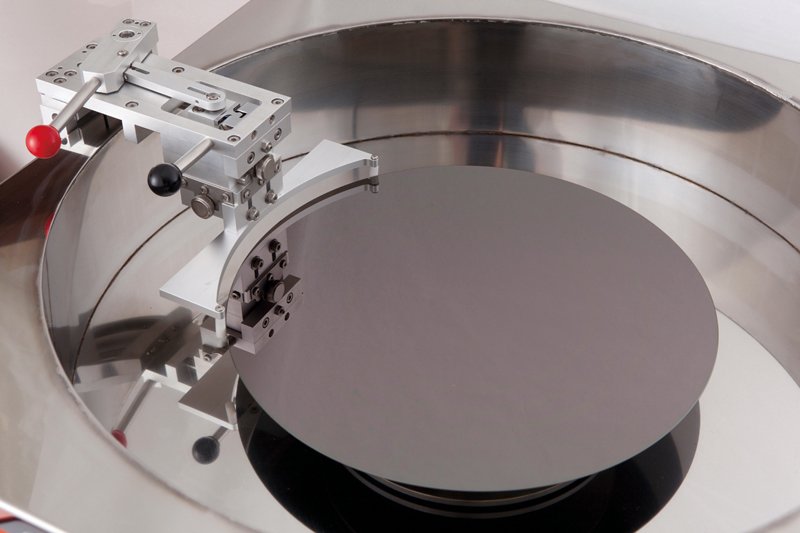

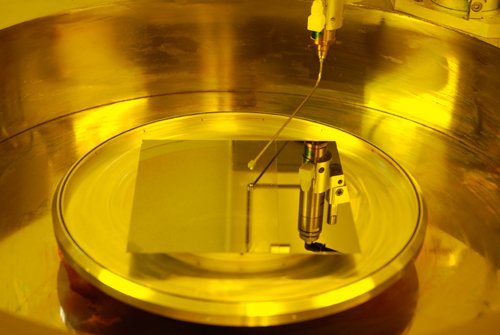

≪Automatic dropping device attached example≫

Coating Thickness Distribution Data

Sample Stages

At Photolithography.com, we offer standard sample stages for our spin coaters to suit your needs. Please feel free to contact us for customization services if you have other requirements.

| ●Sample Stages (standard) | ●Sample Stages (customized) |

For MS-B100 |