Product Information

Developing and Etching Equipment

Compact Developing Equipment for Photolithography / AD-1200

Features

- ■ Capable of puddle development and spray development using a swing nozzle.

- ■ Wetted parts are made of stainless steel to protect against chemicals.

- ■ Easy programming using an LCD touchscreen.

- ■ Expandable for up to three developer.

- ■ Consecutive processing for feeding chemical rinsing, and spin drying.

- ■ Incorporates a pressure pump for feeding chemical.

Product Specifications

| Chamber | Made of stainless steel |

|---|---|

| Substrate size | 1 to 6 in. dia. (150 × 150 mm) |

| Pumping of chemical solutions | Pumped by a built-in pump. |

| Discharge of chemical solutions | Sprayed out (via swing nozzle) |

| Number of steps | 96 steps (with skip and copy functions) |

| Number of program modes | 10 modes |

| Process (standard) | Developer: one line Rinse: one line Backside rinse: one line |

| Developer used | Alkaline developers |

| Rotational speed | 0 to 3,000 rpm |

| Interlocks | Vacuum suction check sensor Interlock for treatment chamber cover Nozzle overrun limiter |

| Power supply | 100 V AC, 4 A |

| Dimensions (in mm, with the door open) | 550 W × 440 H (740 H) × 400 D |

| Weight | 33 kg |

| Main options | Developer thermal management system (pressurization mode) Substrate holders Workbench on which the product is placed |

Note: Specifications are subject to change without notice.

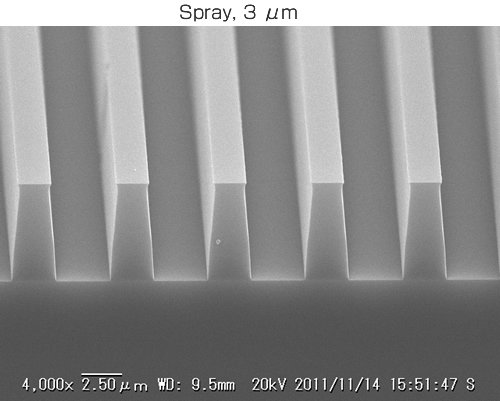

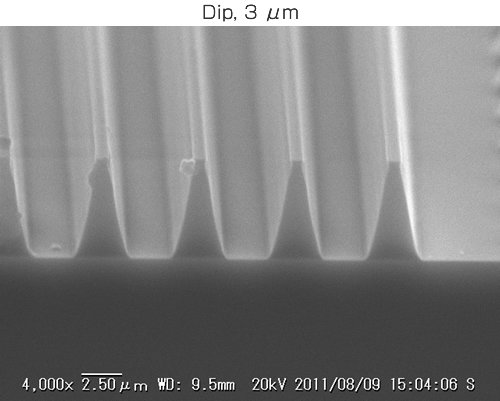

Comparison Images of Spray Development and Dip Development

| Main Equipment and Materials | |

|---|---|

| Resist | AZ P4620 |

| Developer | AZ 400K |

| Spin coater used | MS-B150 |

| Mask aligner used | MA-20 |

| Developing equipment used | AD-1200 |

| Process Conditions | |

|---|---|

| Substrate | 4-inch-dia. silicon wafers |

| Primary treatment | HMDS |

| Coating thickness | >6μm |

| Prebake | 100℃, 90 sec |

| Spray development time | 60 sec |

Note: Postbake was not performed.

Developing Equipment for Photolithography / AD-3000

Features

- ■ Twin swing nozzle spray suitable for large substrates.

- ■ Wetted parts are made of stainless steel to protect against chemicals.

- ■ Easy programming using an LCD touchscreen.

- ■ Expandable to two or three lines of developer.

- ■ Consecutive processing for feeding developer, rinsing, and spin drying.

- ■ Developer are pumped by a pressure tank.

Product Specifications

| Chamber | Made of stainless steel |

|---|---|

| Substrate size | 1 to 12 in. dia. (220 × 220 mm) |

| Pumping of chemical solutions | Pumped by a pressure tank. |

| Discharge of chemical solutions | Sprayed out (via swing nozzle) |

| Number of steps | 48 steps (with skip and copy functions) |

| Number of program modes | 10 modes |

| Process (standard) | Developer: one line (two nozzles) Rinse: one line (two nozzles) Backside rinse: one line |

| Developer used | Alkaline developers |

| Rotational speed | 0 to 3,000 rpm |

| Interlocks | Vacuum suction check sensor Interlock for treatment chamber cover Nozzle overrun limiter |

| Power supply | 200 V AC, three-phase, 15 A |

| Utility | N2:0.6MPa |

| Dimensions (in mm, with the door open) | 720 W × 500 H (910 H) × 520D |

| Weight | 60 kg |

| Main options | Developer thermal management system (pressurization mode) Substrate holders Workbench on which the product is placed |

Note: Specifications are subject to change without notice.

Compact Etching Equipment for Photolithography / ED-1200

Features

- ■ Spray etching equipment with a swing nozzle.

- ■ Wetted parts are made of polyvinyl chloride (PVC) to protect against chemicals.

- ■ Easy programming using an LCD touchscreen.

- ■ Expandable for up to three etchant.

- ■ Consecutive processing for etching, rinsing, and spin drying.

- ■ Incorporates a pressure pump for feeding.

Product Specifications

| Chamber | Made of polyvinyl chloride (PVC) |

|---|---|

| Substrate size | 1 to 6 in. dia. (150 × 150 mm) |

| Pumping of chemical solutions | Pumped by a built-in pump. |

| Discharge of chemical solutions | Sprayed out (via swing nozzle) |

| Number of steps | 96 steps (with skip and copy functions) |

| Number of program modes | 10 modes |

| Process (standard) | Etchant: one line Rinse: one line Backside rinse: one line |

| Etchant used | Acid etchant |

| Rotational speed | 0 to 3,000 rpm |

| Interlocks | Vacuum suction check sensor Interlock for treatment chamber cover Nozzle overrun limiter |

| Power supply | 100 V AC, 4 A |

| Dimensions (in mm, with the door open) | 550 W × 440 H (740 H) × 400 D |

| Weight | 33 kg |

| Main options | Etchant thermal management system (pressurization mode) Substrate holders Workbench on which the product is placed PTFE Chamber |

Note: Specifications are subject to change without notice.

Etching Equipment for Photolithography / ED-3000

Features

- ■ Twin swing nozzle spray suitable for large substrates.

- ■ Wetted parts are made of polyvinyl chloride (PVC) to protect against chemicals.

- ■ Easy programming using an LCD touchscreen.

- ■ Expandable to two or three lines of etchant.

- ■ Consecutive processing for etching, rinsing, and spin drying.

- ■ Etchant are pumped by a pressure tank.

Product Specifications

| Chamber | Made of polyvinyl chloride (PVC) |

|---|---|

| Substrate size | 1 to 12 in. dia. (220 × 220 mm) |

| Pumping of chemical solutions | Pumped by a pressure tank. |

| Discharge of chemical solutions | Sprayed out (via swing nozzle) |

| Number of steps | 48 steps (with skip and copy functions) |

| Number of program modes | 10 modes |

| Process (standard) | Etchant: one line (two nozzles) Rinse: one line (two nozzles) Backside rinse: one line |

| Etchant used | Acid etchant |

| Rotational speed | 0 to 3,000 rpm |

| Interlocks | Vacuum suction check sensor Interlock for treatment chamber cover Nozzle overrun limiter |

| Power supply | 200 V AC, three-phase, 15 A |

| Utility | N2:0.6MPa |

| Dimensions (in mm, with the door open) | 720 W × 500 H (910 H) × 520D |

| Weight | 60 kg |

| Main options | Chemical solution temperature control system (pressurization mode) Substrate holders Workbench on which the product is placed PTFE Chamber |

Note: Specifications are subject to change without notice.